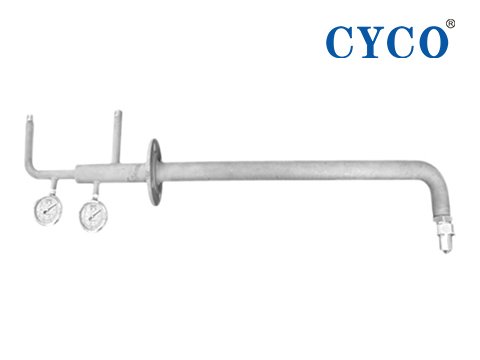

Design Features

1. The nozzles on the CDE series spray guns use large-flow air atomization nozzles, which have multi-stage atomization effects

2. Adopt double-fluid nozzle, and use steam or air as the second fluid

3. In harsh environments, high-efficiency design and three-stage atomization performance can achieve high atomization performance with a small amount of compressed air

4. The spiral nozzle installed inside is the second-stage atomizing nozzle. The design of the large-diameter flow channel of the spiral nozzle can effectively prevent clogging and other harsh fluid environments

Performance parameters

Application

Denitrification spray guns are mostly used in chain furnaces, pulverized coal furnaces, and SNCR denitrification work in cement plants, power plants, steel plants, and waste incineration plants to make NOx emissions meet the requirements of the new national standards. Mainly compressed air is atomized with ammonia water to form fine atomized particles, and then mixed with flue gas to undergo a chemical reaction, thereby purifying harmful gases in the flue gas and meeting the national flue gas emission standards.